Injection Moulding

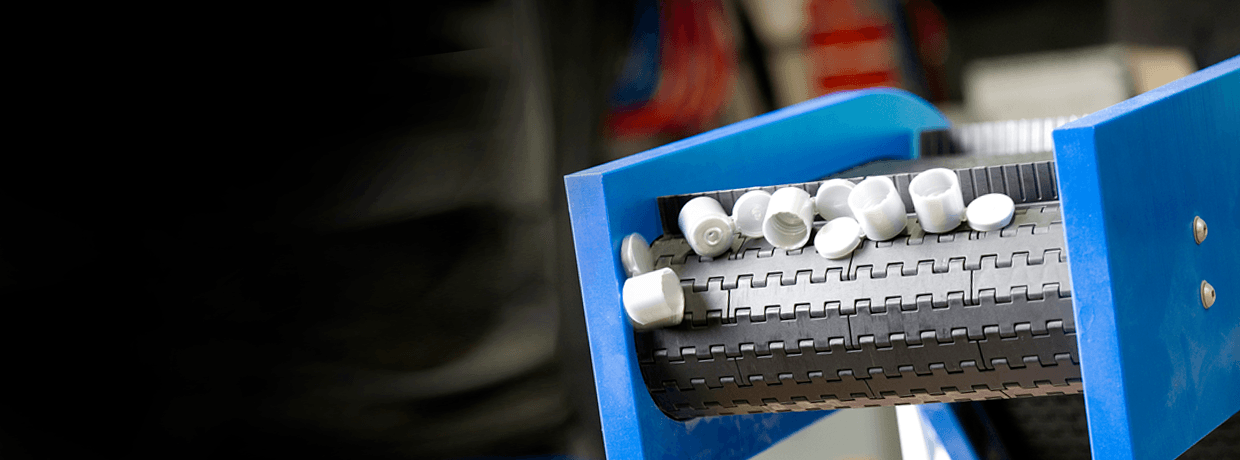

Injection moulding (IM) is the process of manufacturing highly accurate plastic components such as closures, overcaps, and reducer plugs.

Spectra can provide a wide range of off-the-shelf designs or bespoke solutions, tailored to customer needs. Our injection moulded

components are designed to complement our EBM and ISB containers

and offer a total packaging solution.

Packed with Sustainability

When customers take advantage of our single source service for both bottles and closures, they can also greatly reduce their carbon footprint by minimising needless additional transport. What’s more, our closures can be recycled.

Need an Environmental Solution?

We Are: Your Single Source Service Provider

The ability to manufacture everything in-house makes us a genuine ‘single source supplier’ for both bottles and caps. Our fully synchronised delivery commitment provides a stress-free in-house service. We understand that using two separate manufacturers for both bottles and caps can often result in different lead-times that hamper the progress of your packaging project when all you want is to get your product to market.

What are the benefits of the Injection Moulding Process?

Our bottle and cap service eliminates fragmented lead times

We can provide MOQ’s as low as 5,000 pieces for flexibility

Our closures are bore sealed for optimum performance and reliability

Our closures can be custom coloured to your specification

We can decorate our closures with peripheral or top foil blocking

Our closures are tested with stringent quality control measures