We Are:

Independent

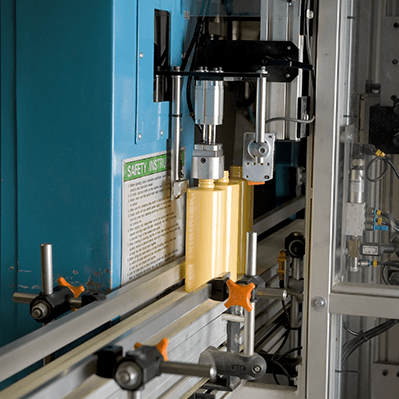

All our products are made to order in-house at our purpose-built facility in the UK. Because we are an independent, privately owned, self-financing business, we can deliver rapid, consistently high results for a wide variety of customers - from large multinationals to small start-up businesses, with total control over quality and lead-times.

Trusted by Leading Brands

We have continued to build strong and lasting relationships with many leading cosmetics and personal care brands since 2008. We are committed to understanding their objectives to add value to their products. In doing so, we can help strengthen their brand, entice more consumers and communicate their core values successfully.

Driven by Innovation

We have always considered innovation as a critical driver for the whole of our business. All well as the products we make, our innovative approach also encompasses the way we operate as a business, including our attitude towards our staff, our customers, our suppliers and any potential impact our practices have on the environment.

We Are: Committed to delivering excellence and innovation whilst minimising our impact on the environment

We Are: Driven by these core values

To ensure outstanding customer service

We adopt a single service standard policy for each one of our valued customers. Whether you are a large global brand or a small start-up business, our desire to provide outstanding service remains the same.

To provide consistent product excellence

We understand that the success of any product can be undermined by poor quality packaging. As such, we continue to ensure every component we make meets the highest levels of quality control for our customers.

To develop innovative solutions

We believe customers should never have to settle for the ordinary, which is why we continue to push the boundaries in plastic packaging. We see innovation as fundamental to our continued success.

To care for the well-being of others

Our social responsibility extends beyond looking at profit. We understand our broader commitment to building a better society and believe in the value our staff and suppliers bring to the business.

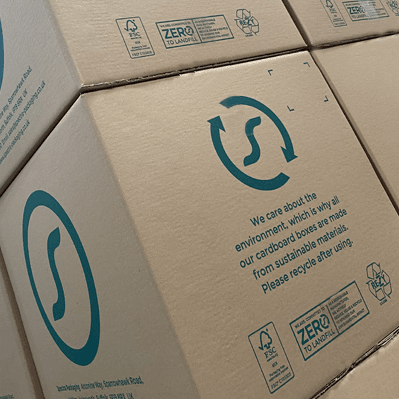

To minimise our impact on the environment

We consider environmental sustainability as a core value. As a responsible manufacturer, we strive to minimise our impact on the environment through working practices and our products.

We Are: Industry experts with a proven heritage

Although we’re a relatively young company, we employ industry experts across all departments within the business. With roots in masterbatch polymer colouring going back over 20 years, we are well placed with proven packaging experience. Since 2008, we have developed an enviable reputation as the go-to supplier for innovative packaging to a broad and diverse range of leading high street brands.

Talk to an expert today:

+44 (0)1986 834190

Delivering excellence, innovation and sustainability since 2008

Manufacturing began at our Broadway Drive site in Halesworth, Suffolk. Initially, we provided extrusion blow moulding, print, design and tooling, but later in the year introduced injection stretch blow moulding and injection moulding. Soon after, we added hot foil blocking to our decoration services and unveiled our first product catalogue.

Over these two years, we introduce Post Consumer Recycled (PCR) packaging in HDPE and PET and peripheral hot foil banding for closures. We also obtained planning permission to build a new purpose-built manufacturing plant and make our debut appearance at Packaging Innovations at the Birmingham NEC.

A pivotal moment in our history sees us move into a new purpose-built site at Sparrowhawk Road, introducing several environmentally-friendly features within the new factory. 2011 also sees us appear at Packaging Innovations, unveiling a range of innovative prototype designs to widespread interest. During this year, we also Spectra continue to strengthen our apprenticeship initiatives.

Environmentally minded, we introduce HDPE and PET sugarcane-based biopolymer packaging. We also present raised printing and seamless printing to our decoration services, which see increased demand. This was also the year we unveiled a new flip-top closure range. As export continues to flourish, we create a dedicated export department and participate in overseas trade shows.

Continued investment resulted in installing hybrid ISB machines, free air cooling within the factory and variable speed compressors. We appear at Packaging Innovations London for the first time, launch our illuminate anti-counterfeiting print and receive recognition at The Luxury Packaging Awards in London with two nominations. During this period, Spectra strengthens its distributor network in France and Scandinavia.

2018 is a landmark year in our history with our 10th anniversary. Expansion building work is complete with machinery installed and fully operational. This was also the year we launched PCR10 – our 10% recycled content op-out initiative. As part of our continued environmental efforts, we also sign up to Operation Clean Sweep. We exhibit in France, Germany and Sweden as well as two UK shows.

A year of recognition, which also includes more exhibitions, continued export growth and environmental endeavours. We staged our first beach clean, formed an internal environmental committee and appeared on BBC Radio to debate plastics. Spectra were also recognised for a 100% recycled custom pack for skincare brand Beached, receiving a highly commended award at the Horner’s Bottlemakers Awards.

A strong start to the year saw two successful exhibitions in Paris and Birmingham. Soon after COVID-19 takes hold, Spectra continued to work through the lockdown as a supplier of essential products, carrying out measures to ensure staff are safe as they work around the clock. We are widely applauded for supporting a range of critical services at the pandemic’s height, including schools, emergency services, prisons and most notably, care homes. The company continues to meet unprecedented demand into the new year.

The launch of a new website featuring MYSPECTRA, a unique, easy-to-access hub tailored to customers specific needs. In response to the imminent plastics packaging tax, Spectra unveiled its PCR30 initiative, with 35% recycled content added to all bottles and commissioned an independent Life Cycle Analysis (LCA) to prove that plastics are still the most environmentally friendly materials. We also supported local Paralympian swimmer Jordan Catchpole, who went on to win gold and was awarded an MBE.

More expansion, with building a new 24,000 sq ft unit facility, increased our total manufacturing capacity to 100,000 sq ft. In April, the Plastics Packaging Tax was introduced, and Spectra rolled out our new PCR30 initiative to support customers. Later in the year, we announced all our rPET bottles would be made from Prevented Ocean Plastics. In March, a donation point was set up at our factory to support families affected by the war in Ukraine. Staff embarked on the Yorkshire Three Peaks Challenge for Macmillan and organised a Couch to 5k running programme.

Spectra broadened its Prevented Ocean Plastics commitment to include recycled HDPE. A team from Spectra visited Bali to witness first-hand the Prevented Ocean Plastics programme in action. Spectra won Business of the Year at the Waveney Business Awards. We also received Bronze at the Environmental Packaging Awards and are shortlisted at the Suffolk Business Awards. Our Spectra products meet Halal and Vegan certification. Spectra provided access to Cycle to Work Scheme for our employees. Spectra also appeared on Sky TV in a programme about Sustainability in Business.